Metal Dock Hood

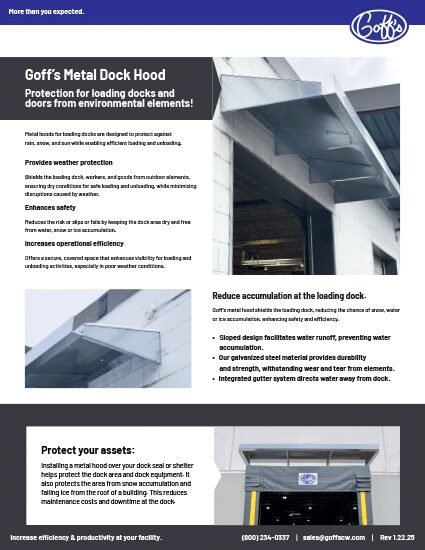

Goff's Metal Dock Hood

Protection for loading docks and doors from environmental elements!

Sloped Metal Dock Hood for loading docks is designed to protect against rain, snow, and sun helping to create a more efficient loading and unloading process. Moreover, it makes a safer environment for workers and truckers.

Shields loading dock and workers from outdoor elements, ensuring dry conditions.

Reduces risk of slips or falls by keeping area dry and free of water, snow and ice.

Secure, covered space that enhances visibility for increased operational efficiency

Reduce accumulation at the loading dock.

Goff’s Metal Dock Hood shields the loading dock, reducing the chance of snow, water or ice accumulation, enhancing safety and efficiency. Furthermore, the sloped design and integrated gutter system facilitates water runoff, directing water away from the dock to prevent accumulation.

Durability & Longevity:

Our galvanized steel material is resistant to corrosion, providing durability and strength to withstand wear and tear from elements.

The ultimate loading dock duo:

Installing Goff’s loading dock metal hood above your dock seal or shelter offers valuable protection for both the dock area and equipment. It helps shield the space from snow buildup and falling ice from the building’s roof, ultimately minimizing maintenance costs and reducing downtime at the dock.

Goff’s Metal Dock Hood is designed to provide your facility with weather protection, safety, and efficiency. Loading dock metal hoods are manufactured in Pewaukee, WI, using what we’ve learned from our 30+ years of innovating products. Moreover, each metal hood includes Goff’s warranty and exceptional customer care & tech support, delivered fast with our industry-leading lead times.

Protection from weather:

Goff’s loading dock metal hood shields your loading dock area from rain, snow, hail, sun or any other outdoor elements. In other words, keeping your dock area dry and safe for loading and unloading operations.

Improved safety:

Metal Dock Hood reduces the risk of slips or falls by keeping the dock area dry and free of water, snow, or ice accumulation! Therefore, this product protects your workers and any other pedestrian around the loading dock.

Workflow efficiency:

Reduce possible downtime due to bad weather, ensuring operations continue. Likewise, it creates a more comfortable environment for employees and other workers.

Submit a quote now to quickly get your sloped Metal Dock Hood ordered!

Easily Installed

Choose to have your metal hood delivered assembled. If you forgo this option, installation instructions will guide your team through set up.

Guaranteed to Last

Every Goff’s Metal Dock Hood comes with a 1 year warranty from failure in normal use due to defects in material/workmanship from date of purchase.

Here to Help

The Goff’s customer care & tech support team will answer any questions you have about your loading dock metal hood. Above all, ensure you get the most out of your investment.

Ready to protect your people and your assets?

Click below for a quote on our Metal Dock Hood to enable efficient loading and unloading.

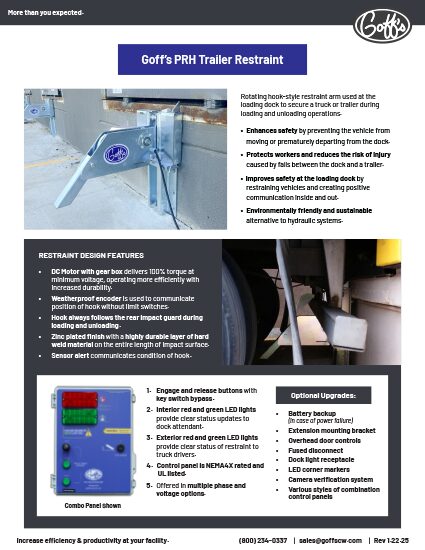

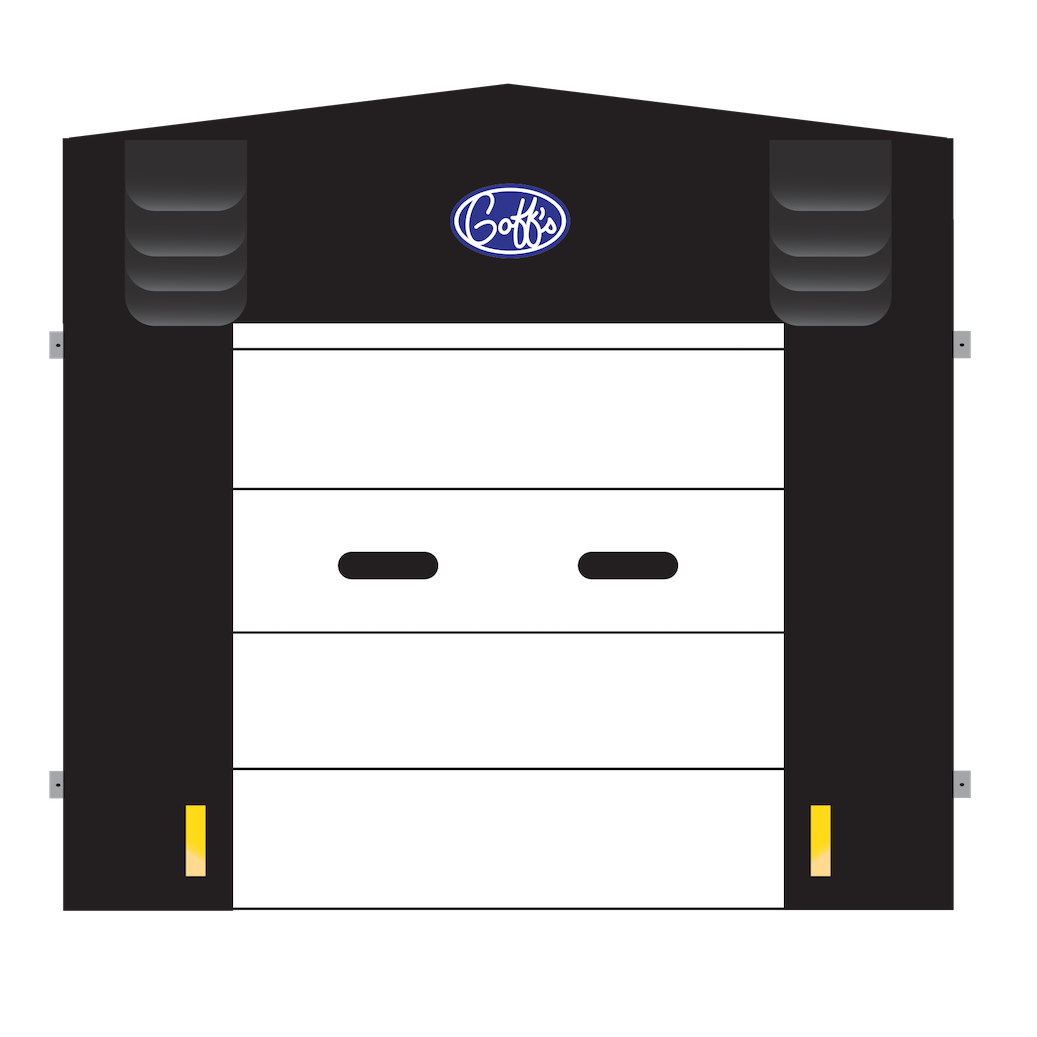

PRH Trailer Restraints

PRH Trailer Restraint

Keep your trailer from moving.

Rotating hook-style restraint arm used at the loading dock to secure a truck or trailer during loading and unloading operations.

Improved Stability

Prevent trailers from shifting or separating from loading docks during loading or unloading.

Worker Protection

Reduces the risk of injury caused by accidents like falls between the dock and a trailer.

Enhanced Safety

Restrains vehicles at the loading dock and creates positive communication inside and out.

Eco-friendly

Environmentally friendly and sustainable alternative to hydraulic restraint systems.

Equip your loading dock with Goff’s PRH Trailer Restraint.

Dependable, unique hook always follows the rear impact guard during loading and unloading.

Zinc plated finish with highly durable layer of hard weld material on the entire length of the impact surface.

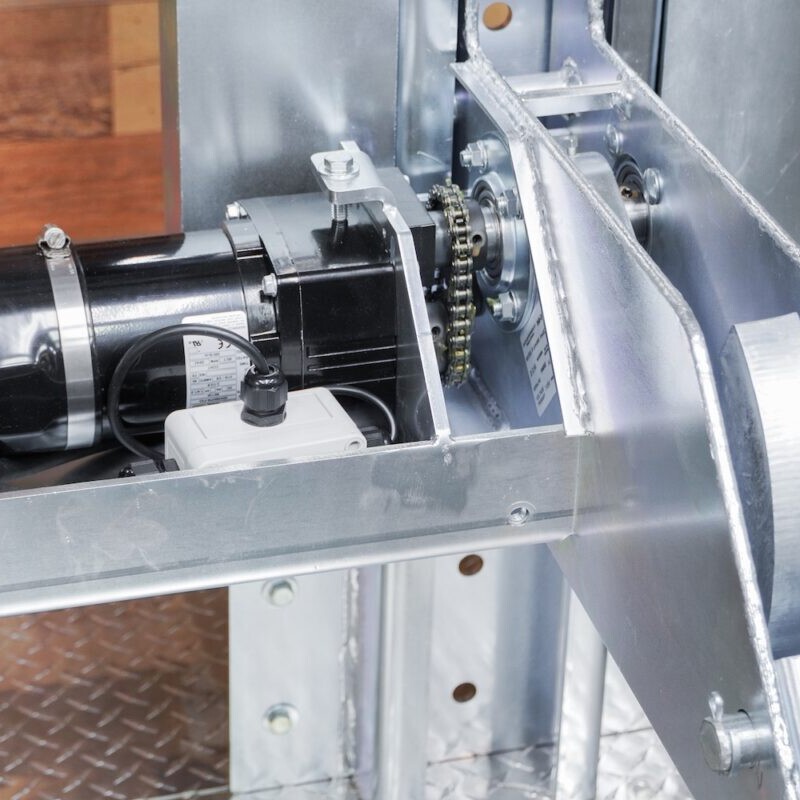

DC Motor with gearbox delivers 100% torque at minimum voltage, operating more efficiently with increased durability.

Goff's premium features:

1. Engage and release buttons with key switch bypass

2. Sensor alert communicates condition of hook

3. Interior red and green LED lights provide clear status updates to dock attendant

4. Control panel is NEMA4X rated and UL listed

5. Offered in multiple phase and voltage options

6. Exterior red and green LED lights provide clear status of restraint to truck drivers

No electrical available? No problem.

Goff’s durable Clean Guard Doors are available with a chain hoist operator with a stainless steel cover. This chain hoist device includes an integrated brake, holding the door panel securely at any point in the opening. The 4:1 ratio provides easy door opening with minimal effort, making it a great option for low traffic openings.

Battery backupExtension mounting bracket

Overhead door controls

Fused disconnect

Dock lock receptacle

LED corner markers

Camera verification system

Various combo control panels

Motion Sensors

Automatically activate your door without the need for remotes or buttons.

Remote Control

Operate your door remotely from forklifts & vehicles to maintain productivity.

Pull Cord

Easy operation in close proximity for pedestrians, forklift, and vehicles drivers.

NEMA4 Controller

NEMA4 rated push button station available for outdoor or moisture-prone areas.

Goff’s trailer restraint is the superior option compared to others on the market. Each trailer restraint includes features that others don’t, has exceptional customer care & tech support, and is delivered fast with our industry-leading lead times.

Why do I need a trailer restraint?

Trailer restraints are essential to loading dock safety. A vehicle moving or prematurely departing from the loading dock while operations are happening is extremely dangerous. Not only can this cause damage to goods, but also can be extremely harmful to employees and truck drivers. Goff’s PRH Trailer Restraint hooks onto the back of a trailer, ensuring it doesn’t move during loading and unloading, protecting workers and reducing accidents.

What’s different about Goff’s restraint?

Our loading dock restraint has a zinc plated finish with a highly durable layer of hard weld material on the entire length of the impact surface. Furthermore, the hook on our restraint always follows the rear impact guard during loading and unloading to ensure there is always positive contact. Overall, there are so many great features about our restraint. Check out the Downloads tab for more information on Goff’s PRH Trailer Restraint!

Custom options:

Though our trailer restraint comes with so many features, we still have options upgrades! These include: a battery backup in case of power failure, extension mounting bracket, overhead door controls, fused disconnect, dock light receptacle, LED corner markers, camera verification system, and various combo control panel styles.

Interested in getting a quote? Click here to get your restraint!

Goff's Advantage

Our restraint stands out by offering more features tailored to your needs, delivering greater value and versatility compared to other options.

Guaranteed to Last

Every Goff’s PRH Trailer Restraint comes with a 1 year warranty from failure in normal use due to defects in material/workmanship from date of purchase.

Here to Help

The Goff’s customer care & tech support team will answer any questions you have about your restraint. Above all, ensure you get the most out of your investment.

Make your loading dock safer with Goff's trailer restraint!

Click below to get a quote on our loading dock restraint.

Pit-Style Dock Levelers

Goff's Pit-Style Dock Levelers

For heavy-duty load capacities.

Designed to withstand heavy loads and frequent use, Goff’s Pit-Style Dock Levelers are used to bridge the gap between your loading dock and a trailer for efficient loading and unloading. Recessed in a pit at the loading dock, pit-style levelers are flush with the dock when not in use, and can be easily activated for a smooth loading process.

Application flexibility.

Pit-style levelers can accommodate a wide range of truck heights, making it suitable for any facility.

Long-term durability.

Built to take on frequent loading dock use and can handle heavy loads, making it a reliable and durable loading dock necessity.

Quick & easy operation.

Manually or hydraulically operated with a simple chain or button, pit-style levelers can be deployed simply for quick use.

CONSTRUCTION

Goff’s Edge of Dock Levelers are designed for light to moderate capacities with a range up to 30,000 lbs. All EOD’s are built with a durable high tensile strength steel, steel bumper blocks with molded rubber bumpers, 16″ bumper projection and milled lip edge for smooth tire rollover.

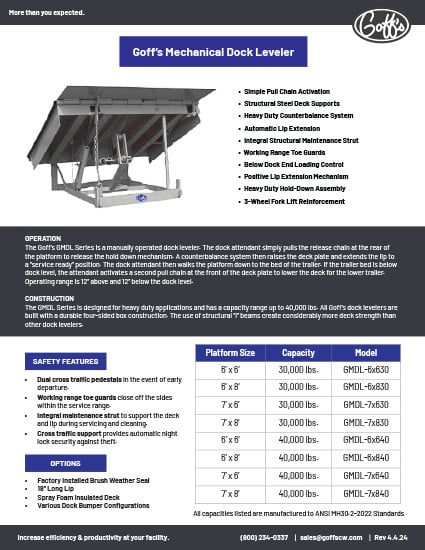

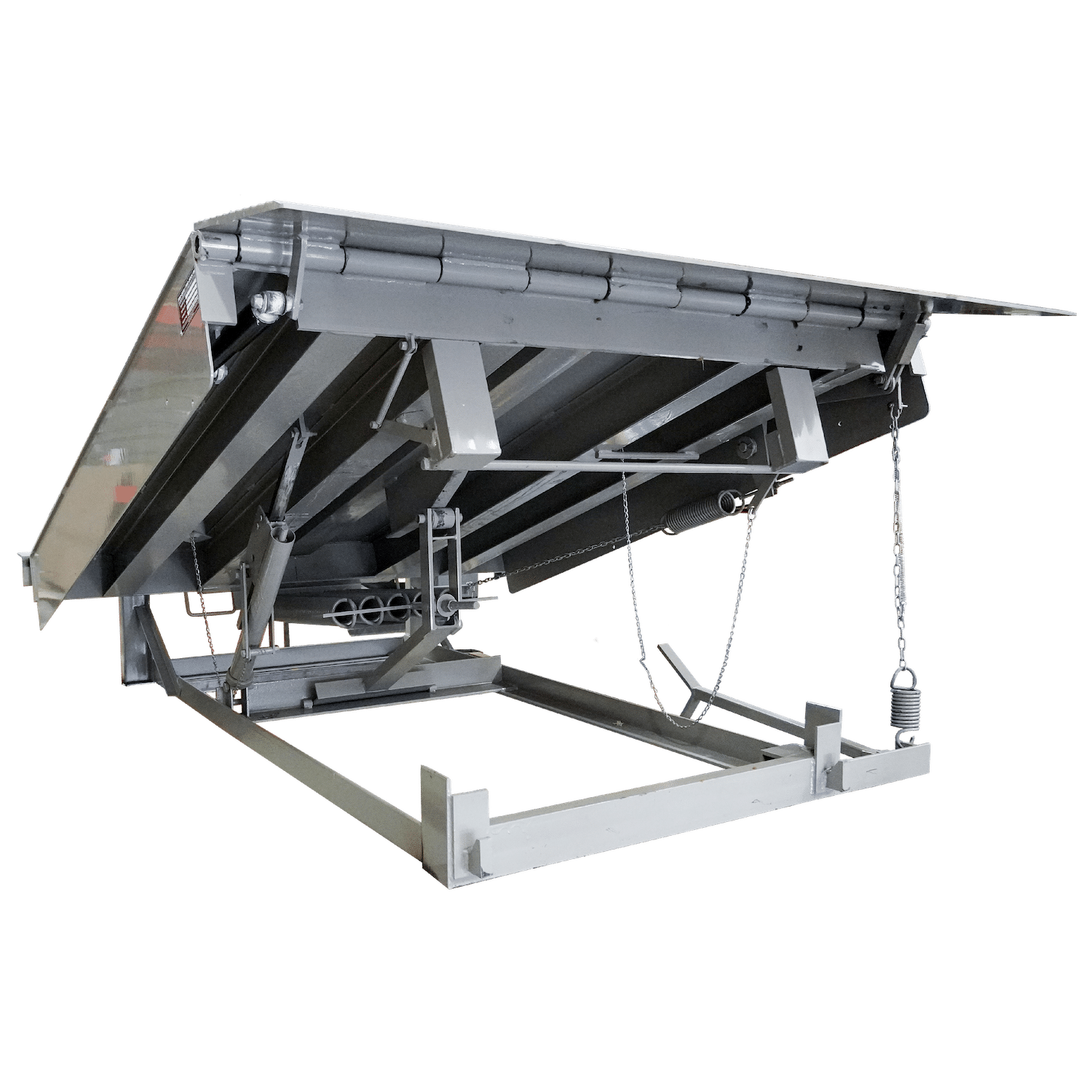

Mechanical Pit-Style Leveler

Goff's manual pit-style leveler is operated by simply pulling the release chain at the rear of the platform to activate the service ready position.

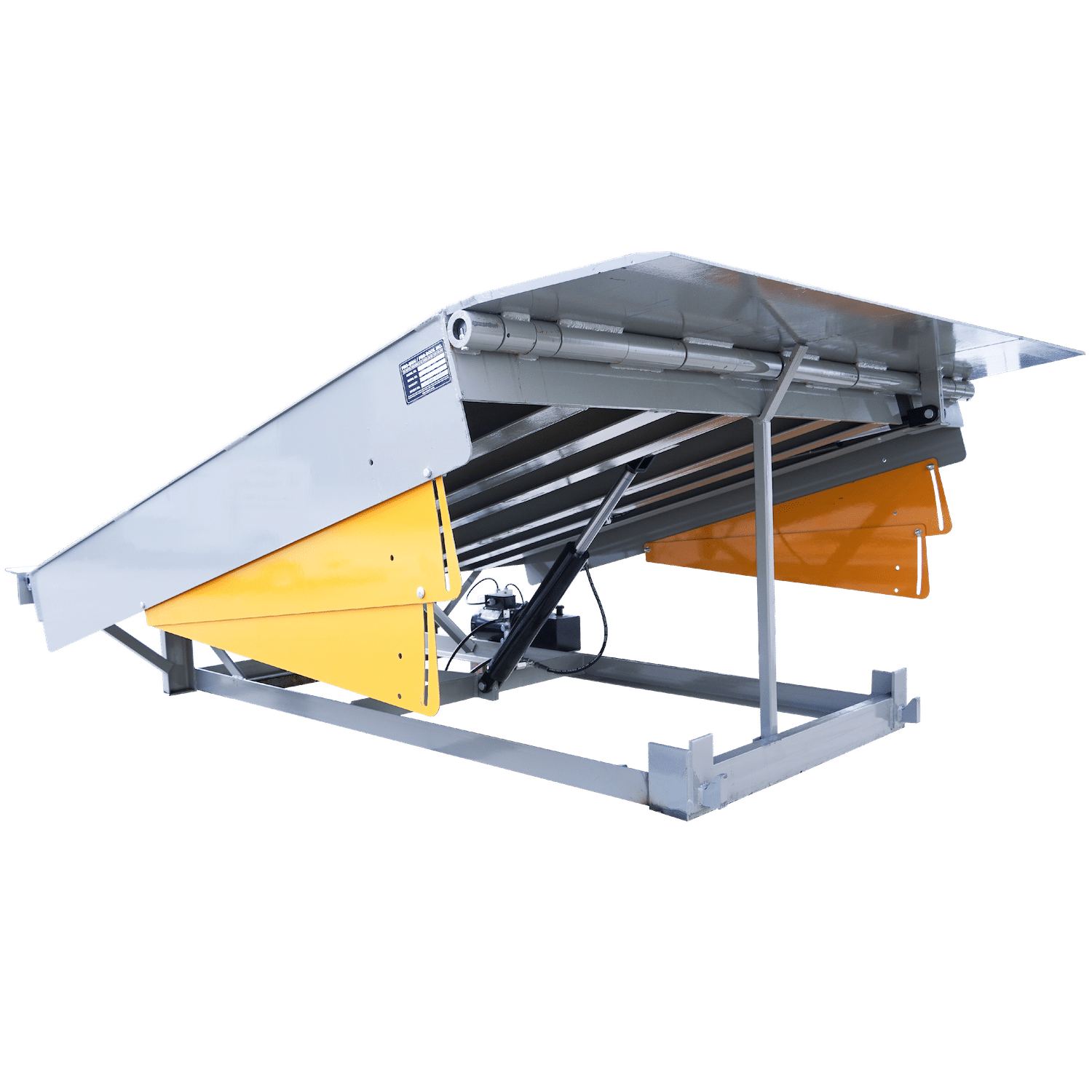

Hydraulic Pit-Style Leveler

Goff's hydraulic pit-style leveler is operated by a simple push of a button to control the platform to activate the service ready position.

Air-Powered Pit-Style Leveler

Goff's air-powered pit-style leveler is operated with a dual chamber air bag system to control the platform, activating the service ready position.

Safety Barrier Lip

Request a safety lip to provide full protection and prevent lift trucks from driving off the edge of the dock in both the stored cross traffic and below dock end loading position.

Dock Leveler Pit Seal

Our pit seal forms a tight barrier around the dock leveler’s perimeter, minimizing energy loss, preventing rodents from entering, and blocking the infiltration of outdoor elements.

Piano-Style Hinges

Our Pit-Style Dock Levelers are built with piano-style hinges that run the full width of the deck to evenly distribute weight and stress from heavy loads.

Safety Features:

Dual cross traffic pedestals

Full range toe guards

Integral maintenance struts

Structural lip keepers

Save Energy. Increase Comfort.

Goff’s Dock Leveler Pit Seal effectively forms a tight barrier around the dock leveler’s perimeter, significantly minimizing energy loss, preventing rodents from entering, and blocking the infiltration of outdoor elements.

Factory installed brush weather seal

Spray foam insulated deck

Custom bumper size

Goff’s pit-style levelers provide an easy way to improve efficiency at the loading dock for those heavy and frequent loading dock jobs. Furthermore, each pit-style dock leveler comes with Goff’s best-in-class warranty and exceptional customer care & tech support, delivered fast with our industry-leading lead times.

Our models:

Choose between our different operations: mechanical, hydraulic, and air-powered. Our mechanical pit-style leveler has a simple pull-chain activation. In other words, the attendant simply puts the release chain at the rear of the platform to activate the system. The hydraulic option can be operated with the push of a button, therefore being an easier option. The air-powered is similar to the hydraulic in that it is powered with a push button, however, it is designed with a dual-chamber air bag system.

Our construction:

Goff’s line of pit-style levelers are designed for heavy-duty applications. Moreover, all levelers are built with a durable four-sided box construction. The use of structural box beams or “I” beams create considerably more deck strength. Overall, these units are designed for heavy-duty applications.

Check out the Download tab for more information on everything pit-style leveler related!

Goff's Warranty

Goff’s offers a 5-year structural warranty for the pit-style series and 1-year on all other components. Extended structural warranties are available with complete application survey and review for approval.

Fastest Industry Lead Times

With the industry’s fastest lead times, you can have your complete pit-style leveler system installed and active to provide maximum efficiency at your facility in no time. Therefore minimizing downtime & maximizing productivity.

Customer Care & Tech Support

The Goff’s customer care & tech support team is available to answer any questions you have about pit-style leveler making sure you not only get the most out of your investment, but ensure it runs smoothly for years to come.

Ready to increase efficiency at the loading dock?

Click below to get a quote on our Pit-Style Dock Levelers!

Weather Wall

Goff's Weather Wall

Protect against harsh elements with Goff's Weather Wall loading dock header seal.

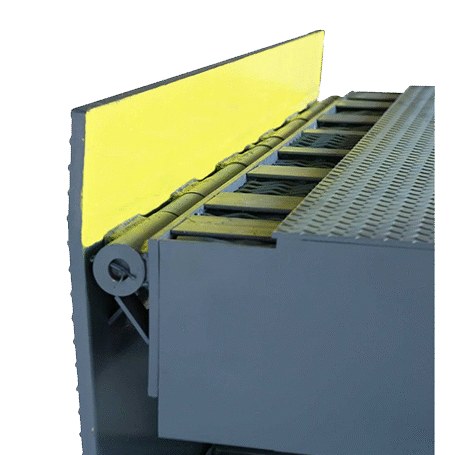

Goff’s Weather Wall loading dock header seal was designed to create additional protection from the elements at your loading dock. The Weather Wall diverts water away from your loading dock as a trailer backs into position.

Made in the USA and quickly shipped to your facility for expedited installation.

Protects transitioning product from environmental damage and outside contaminants.

Reduces energy loss by eliminating unwanted airflow.

Keeps employees safe, comfortable, and productive by removing potentially dangerous outside elements.

Weather Wall Protects Against Elements at the Dock.

Our loading dock header seals protect loading docks from moisture and weather infiltration, reducing expensive water damage to product shipments. A backing trailer automatically positions the seal into place to defer water away. Additionally, a tapered head frame is featured for quick water drainage.

Quick & Easy Replacement

Not only is the Weather Wall as a whole an easy addition to increase protection as a rain sealing system on your dock, but replacing the “wiper” seal is also easy! The wiper seal can become worn over time. It is attached by velcro so a quick swap makes for an easy replacement reducing downtime and maintenance costs.

Support Brackets

The Weather Wall is secured with heavy duty support brackets. This creates a stable mounting for use at any dock.

Treated Lumber

Head framing is structured with KDAT treated lumber to minimize the natural tendencies of wood and preventing warping or shrinking as it endures the outdoor elements.

40oz Vinyl

High density foam seal is protected by 3 layers of 40oz reinforced high tear and high abrasion vinyl.

Height Range

Goff’s Weather Wall rain sealing system is available for trailers 12’9″ to 13’6″ high.

Increase Protection At Your Loading Dock:

Go one step further for your loading dock protection and create a full dock door barrier between the outside harsh weather and a trailer. Goff’s seals and and shelters create a positive seal around the sides and top of the trailer to help save energy in your facility and separate out harsh weather conditions creating a more comfortable environment for workers.

Parameters that determine sizing of your Weather Wall:

Dock height, bumper projection, drive approach angle, dimensions of existing dock seals or shelters, dock height, types of trailers present at the dock.

Goff’s Weather Wall was designed to create additional protection from the elements at your loading dock. This loading dock header seal diverts water away from your loading dock as a trailer backs into position. Utilizing the Weather Wall rain sealing system protects transitioning product from environmental damage and outside contaminants. It reduces energy loss by eliminating unwanted airflow. Additionally, it keeps employees safe, comfortable, and productive by removing potentially dangerous outside elements.

Weather Walls are manufactured in Pewaukee, WI using what we’ve learned from our 30+ years innovating curtain walls. Moreover, each loading dock header seal includes Goff’s best-in-class warranty and exceptional customer care & tech support, delivered fast with our industry-leading lead times.

Increased Protection Saves You Money

Protecting your loading dock with Goff’s Weather Wall is a key factor in keeping deliveries and outbound product safe from the elements. Reduce expensive water damage by preventing moisture and weather infiltration into your dock area. Not to mention, you’ll be saving on energy costs by keeping out unwanted weather conditions and holding in your optimal temperatures.

How To Get Started

You can incorporate a Weather Wall rain sealing system with your new dock seal and shelter order. Ordering a stand-a-lone Weather Wall is an option for facilities that just need to keep rain water out of the loading dock area. Weather Walls can also be added to your currently installed dock seal and shelter for increased protection.

Request a quote now to quickly get your Weather Wall ordered and start increasing protection and safety at your facility!

Protect against harsh environments at your loading dock.

Click below to get a quote on your Weather Wall now.

Edge of Dock Levelers

Goff's Edge of Dock Levelers

For light to moderate load capacities.

Bridge the gap between a loading dock and a truck trailer. Goff’s cost-effective alternative to pit-style dock levelers are mounted to the edge of the loading dock and are used in situations where the height difference between the dock and the trailer are inconsistent and the load capacity is moderate.

Cost-effective solution.

Edge of Dock Levelers are a more budget-friendly option to pit-levelers, providing an easy way to improve efficiency at the loading dock.

Simple installation.

Mounted right to the edge of your existing loading dock, they are easy to install creating an efficient operation that can be used right away.

Quick & easy operation.

Manually or hydraulically operated with a simple handle or button, edge of docks can be deployed simply for quick loading and unloading.

CONSTRUCTION

Goff’s Edge of Dock Levelers are designed for light to moderate capacities with a range up to 30,000 lbs. All EOD’s are built with a durable high tensile strength steel, steel bumper blocks with molded rubber bumpers, 16″ bumper projection and milled lip edge for smooth tire rollover.

Our GMEOD series is manually operated. The dock attendant simply inserts the activation bar into the unit and pulls downward to engage the platform and lip. The attendant pushes the activation bar forward to put the lip to the “service ready” position.

- Simple pull/push bar activation

- Dual extension spring lifting mechanism

- Positive lip extension mechanism

- 5″ operating range above & below dock level

Our GHEOD series is a hydraulically operated edge of dock leveler. The dock attendant simply pushes the button to hydraulically position the dock leveler to the “service ready” position.

- Simple push button activation

- Fully hydraulic lip and deck cylinder

- Available in multiple phase & voltage options

- 5″ operating range above & below dock level

[posts_table post_type=”documents” columns=”image,title,tax:document_category,tax:document_tag,button” term=”document_tag:edge-of-dock-levelers” rows_per_page=”10″]

16" Refer Lip

12" Transition Plate

Formed Angle - 12"w x 12"h x 120"l

Goff’s Edge of Docks provide an easy way to improve efficiency at the loading dock. Each Edge of Dock Leveler come with Goff’s best-in-class warranty and exceptional customer care & tech support, delivered fast with our industry-leading lead times.

Our two options:

Choose between our two different operations: mechanical and hydraulic. Our mechanical EOD has a simple pull/push bar activation. The attendant simply puts the handle into the unit and pulls downward to activate. The hydraulic option can be operated with the push of a button, therefore being an easier option. This comes in multiple phase and voltage options.

Our construction:

Goff’s line of Edge of Dock Levelers are built with high tensile strength steel, steel bumper blocks with molded rubber bumpers, 16″ bumper projection and has a milled lip edge for smooth tire rollover. Overall, our units are designed for light to moderate applications.

Check out the Download tab for more information on everything EOD related!

Goff's 1 Year Warranty

Goff’s warranty package for the Edge of Dock series from failure in normal use and defects in material and workmanship is covered for a period of 1 year as approved by Goff’s tech support team. Our team will help to keep you up and running.

Fastest Industry Lead Times

With the industry’s fastest lead times, you can have your complete Edge of Dock system installed and active to provide maximum efficiency at your facility in no time. Therefore minimizing downtime & maximizing productivity.

Customer Care & Tech Support

The Goff’s customer care & tech support team is available to answer any questions you have about Edge of Dock Leveler making sure you not only get the most out of your investment, but ensure it runs smoothly for years to come.

Ready to increase efficiency at the loading dock?

Click below to get a quote on our Edge of Dock Levelers!

Dock Seals & Shelters

Goff's Dock Seals and Shelters

Separate harsh environments at the loading dock.

Goff’s Dock Seals and Dock Shelters are your solution to creating a barrier between the outside harsh weather and a trailer at the loading dock. Our seals and shelters create a positive seal around the sides and top of the trailer to help save energy in your facility and separate out harsh weather conditions creating a more comfortable environment for workers.

Create a positive seal on the top and both sides of the trailer increasing efficiency.

Creates a barrier from harsh weather conditions for trailers at the loading dock.

Helps save on energy by reducing your facilities heating & cooling costs.

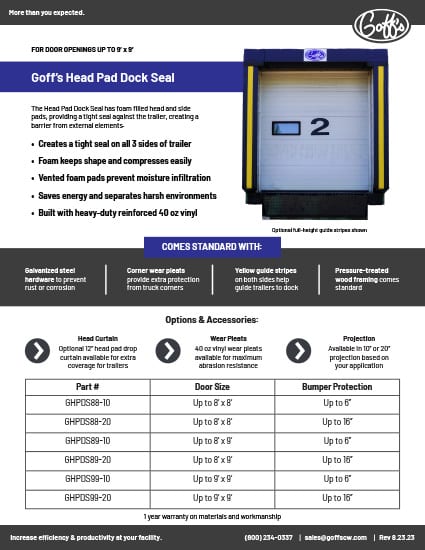

Head Pad Dock Seal

Goff's Head Pad Dock Seal has foam filled head and side pads provide a tight seal against the trailer, creating a barrier from external elements.

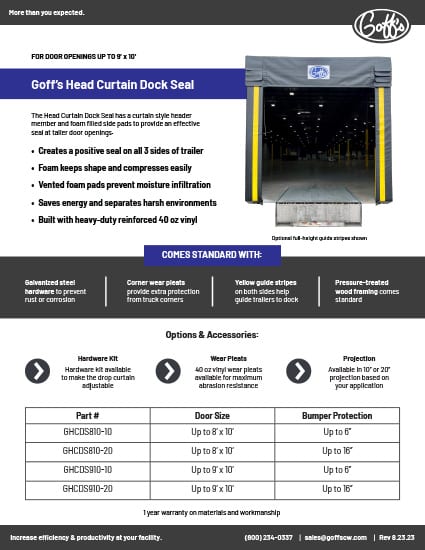

Head Curtain Dock Seal

Goff's Head Curtain Dock Seal have a curtain styler header member and foam filled side pads provide an effective seal and offer the most economical solution.

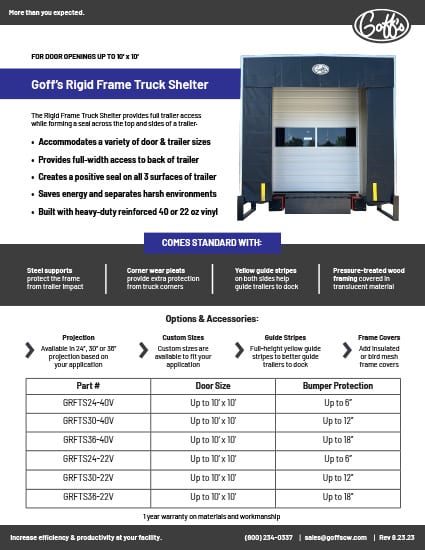

Rigid Frame Truck Shelter

Goff's Rigid Frame Truck Shelter provides full-width access to the back of the trailer, while forming a seal across the top and sides of the trailer.

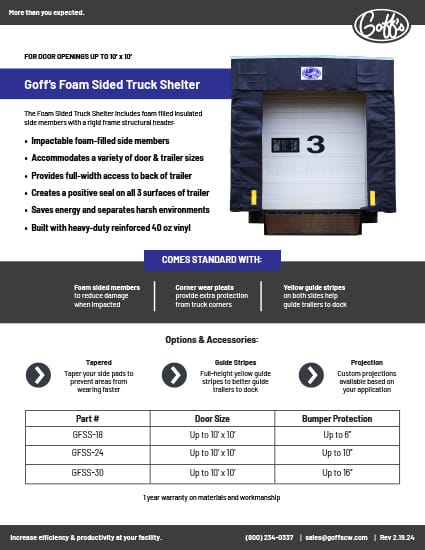

Foam Sided Truck Shelter

Goff's Foam Sided Truck Shelter includes foam filled insulated side members with a rigid frame structural header to provide a seal for the trailer.

Head Pad Dock Seal

Goff's Head Pad Dock Seal has foam filled head and side pads provide a tight seal against the trailer, creating a barrier from external elements.

Head Curtain Dock Seal

Goff's Head Curtain Dock Seal have a curtain styler header member and foam filled side pads provide an effective seal and offer the most economical solution.

Flexible Frame Truck Shelter

Goff's Flexible Frame Truck Shelter pulls back on impact, reducing any frame damage, ultimately extending the working life of the shelter.

Rigid Frame Truck Shelter

Goff's Rigid Frame Truck Shelter provides full-width access to the back of the trailer, while forming a seal across the top and sides of the trailer.

Foam Sided Truck Shelter

Goff's Foam Sided Truck Shelter includes foam filled insulated side members with a rigid frame structural header to provide a seal for the trailer.

All dock seals and shelters come standard with:

Guide Stripes

Yellow guide stripes on both sides to help guide trailers to the dock.

Wear Pleats

Wear pleats in both upper corners provide extra support from truck corners.

Every space is different. Make sure you have everything that is required to make your loading dock a safe and efficient area.

88-8 Laminated Wheel Chock

Wheel Chocks prevent catastrophic accidents. Available with 15′ or 20′ chain options and sign.

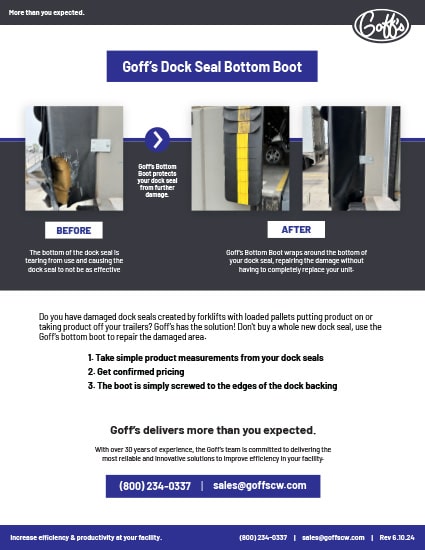

Dock Seal Bottom Boot

Goff’s Bottom Boot wraps around the bottom of your dock seal, repairing any damage without having to completely replace your unit.

Dock Blocker

Easy operation in close proximity for pedestrians, forklift, & vehicle drivers.

Shelter + Metal Hood

Available only with our Foam Sided Shelter, get double the protection with this duo on your loading dock.

Integrated Weather Wall

Available with both our Foam Sided Shelter and our Rigid Frame Shelter, for added protection at the dock.

Dock Seals and Shelters:

Loading docks play a crucial role in the success of your supply chain operations, which ultimately helps your business generate revenue. Ensuring that your loading dock is efficient, safe and productive is the only way to achieve the goal of being successful at the loading dock. Both dock seals and shelters include Goff’s best-in-class warranty and exceptional customer care & tech support, delivered fast with our industry-leading lead times.

Benefits:

Goff’s dock seals and shelters help you maintain environmental protection at your loading dock by keeping rain, snow, sun or even pests out. As a result, keeping your space free of hazards and protecting product from contaminants. Another benefit is safer working conditions for your employees which in turn increases productivity and confidence.

When you add a dock seal or shelter to your loading dock, you will be sealing a gap between the dock and trailer to maintain indoor temperatures preventing energy loss or even product loss. As an added bonus, this keeps your employees happy and comfortable.

Optional Add-ons:

There are a few add-ons you can select to have along with your dock seal or shelter. Including Wheel Chocks adds a safety element that prevents trailer creep while users are entering and exiting the truck trailer.

Ask your distributor or Goff’s rep about our Dock Seal Bottom Boot! Rather than buying an entirely new dock seal when damage occurs, we can outfit you with a Bottom Boot to wrap around the bottom of your seal, repairing any damage.

Finally, we have Dock Blockers available to toss into any open space around the dock that might be missed by a dock seal or shelter. This helps to further prevent any outside elements from getting through the cracks.

Learn More:

Check out the Download tab for more information on everything dock seal and shelter related. You can also head over to our Behind The Curtain Blog to learn more about Dock Seals and Shelters.

Goff's Warranty

Goff’s offers a warranty for all dock seals & dock shelters for 1 year on all material and workmanship as approved by Goff’s tech support team to keep your facility running efficiently. See Product Warranties document for all of Goff’s warranties.

Fastest Industry Lead Times

With the industry’s fastest lead times, you can have your seal or shelter installed to provide maximum efficiency at your facility in no time. Therefore minimizing downtime & maximizing productivity.

Customer Care & Tech Support

The Goff’s customer care & tech support team is available to answer any questions you have about your seals and shelters, making sure you get the most out of your loading dock investment.

Ready to outfit the loading docks at your facility?

Click below to get a quote on our line of dock seals and dock shelters to create a more efficient space for trailers at the loading dock!